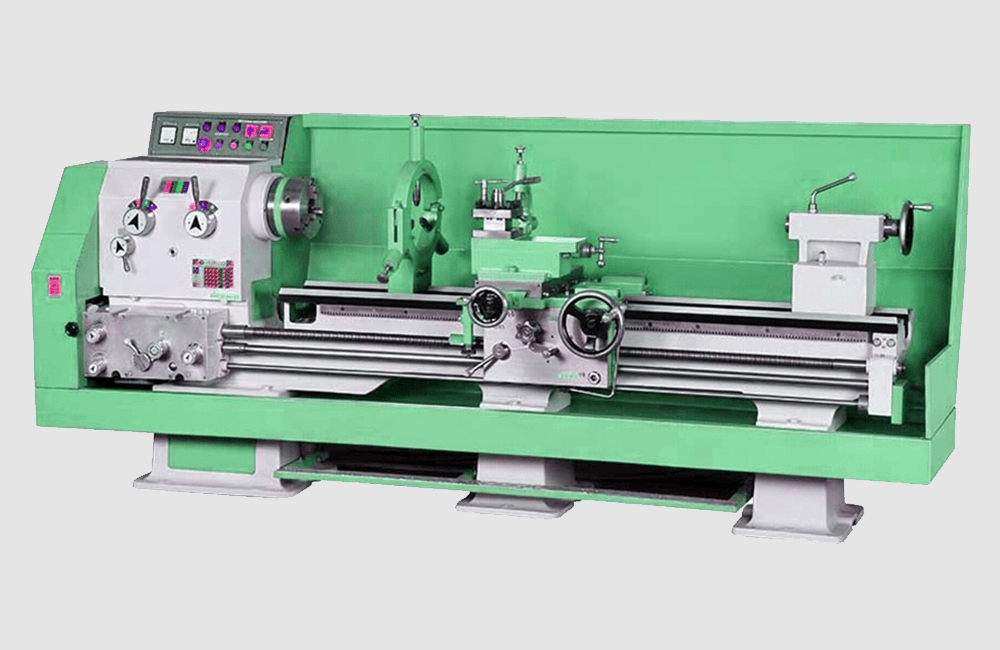

HEAVY DUTY ALL GEAR LATHE

Rajlaxmi Machine Tools – HMP offer high quality Heavy Duty Lathe Machine to meet all your requirements. They are designed to generate objects that have symmetry about an axis of rotation. These lathes are used for precisely machining stiff materials. The devices incorporate the recent technology to ensure improved performance. The machine is economical along with features like robust, sturdy and efficient. The products are manufactured are precise and highly accurate. These Heavy Duty Lathe Machines are equipped with dedicated features like ground headstock spindles and stout one piece planar lathe beds which provide for a solid base and simultaneously facilitating seamless parallel movement of carriage and tailstock in alignment with the axis of the spindle. The alloy steel is used to provide potency and sturdiness to the machine for lasting durability. A specialized oil pump is used which helps to lubricate the rotating spindles and bearings in order to give more power to the machines by neutralizing the inner frictions and tensions within the lathe mechanism and also assists in the process of cooling overheated parts.

Features & Applications

- Flame Hardened bed ways

- Flame Hardened bed ways

- Chuck back plate 1 no

- Centre Adaptor

- Tool Post Spaner

- Dead Centre (MT-4)2 nos.

- Motor Pulley,

- Norton Gearbox

- Change gear set – 1(For metricand inch both)

- Thread Dial indicator

Extra Accessory:

- Face plate

- Carrier plate

- Steady rest

- Follow rest

- Dog/ True Chuck

- Taper turning attachment

- Coolant Pump with Tank and fitting

- Rear tool post with extended cross slide

- Electrical Switch shaft and chip guard

- Electrical Motor

- Panel board

- Wirings

- Push button Switches

- V-belts and fittings

Specifications

| MAIN SPINDLE SPECIFICATION | ||

| Type of Spindle Nose | A 2 – 6 | |

| Spindle Morse Taper | MT-6 | |

| Spindle Adapter Morse | MT-4 | |

| Taper Spindle Speeds | 12 (30, 43, 55, 85, 115, 160, 210, | |

| Nos. / RPM / Range | 285, 400, 545, 785, 1060. RPM ) | |

| Spindle Mounting on | Taper Roller Bearings | |

| THREADS SPECIFICATION | ||

| Nos. of Threads / Range For Fully Orton Gearbox) |

Metric : Inch : | 17 / 0.5 mm To 15 mm Pitch 40 / 2 to 60 TPI |

| FEEDS SPECIFICATION | ||

| Nos. of Feeds / Range For Fully Norton Gearbox) |

Longitudinal : Cross : | 40 / 0.066 to 2 mm / rev. of spindle 40 / 0.0165 to 0.5 mm / rev. of spindle |

| ELECTRICALS SPECIFICATION | ||

| Electric motor of 3 HP / 2.25 k.w. | 3 Phase | 1440 RPM with Panel board wirings |

| over load relay | Push button switches | V-belts and fittings |

`

| TECHNICAL DATA | |||

| MODEL | ADMIT BETWEEN CENTRES | LENGTH OF BED | Approx. Weight in kgs. |

| Nett. | |||

| AHD-1 | 525 mm | 1675 mm (5’-6”) | 1450 |

| AHD-2 | 1000 mm | 2135 mm (7’) | 1500 |

| AHD-3 | 1600 mm | 2745 mm (9’) | 1650 |

| AHD-4 | 1900 mm | 3050 mm (10’) | 1900 |

| AHD-5 | 2500 mm | 3660 mm (12’) | 2050 |

| AHD-6 | 3100 mm | 4270 mm (14’) | 2350 |

| AHD-7 | 3710 mm | 4875 mm (16’) | 2700 |

| Details | STD C.H. | 12” C.H. |

| Centre Height over flatbed ways | 267 mm | 305 mm |

| Swing Over Bed | 525 mm | 600 mm |

| Swing Over Cross Slide | 300 mm | 375 mm |

| Swing In Gap | 830 mm | 910 mm |

| Length of Gap in front of Face Plate | 200 mm | 200 mm |