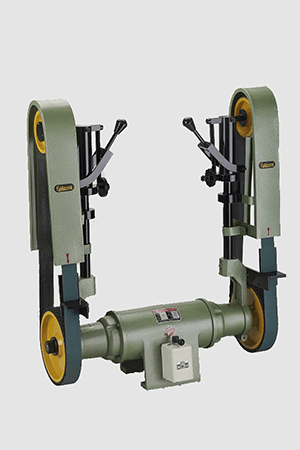

ABRASIVE BELT GRINDER (DOUBLE SIDE) MANUFACTURER

We are the Leading Dealer, Supplier, Exporter and Whole seller of RAJLAXMI Abrasive Belt Grinder, Abrasive Belt Grinding Machine and Rubber Wheel Abrasive Belt Grinding Machine in Rajkot, Gujarat, INDIA. “Rajlaxmi” Make Abrasive Belt Grinder machine offered range of grinder is manufactured from best quality input factors and adopting latest methods of fabrication. In addition to this, offered grinders are manufactured under the supervision of skillful and experienced professionals. Moreover, offered range of grinder is highly demanded by the clients for its high strength and performance. We are providing these RAJLAXMI grinders at reasonable market price. Versatile machine generally requested for Forge Shops, Press Shops, Ferrous & non Ferrous Foundries, Fabrication Shops, Engineering Industries, Plastic & Glass Industries, Rubber & leather industries and wood industries. Rate of material removal is optimum. Excellent ground finish obtained and High rate of production.

Use of best quality stamping and die cast rotors Dynamically Balanced rotor minimize vibrations and ensure smooth running. Telescopic tendering arm for belt tensioning. Construction of the machines is made sturdy and robust to offer vibration free performance. Machine provided with One No. this belt grinder contain with Abrasive Belt, Serrated Rubber Contact Wheel, Rotary Switch /Starter and Safety Belt Guard. Machines available in two Models I.e. Single ended and Double ended. Machines are available in Bench type or Pedestal type. We have Available size in Abrasive Belt Grinder Machine is 2000 x 50 mm, 50 x 2000 mm.

Features & Applications

Precision design

- ON-OFF Switch, Belt Guard Cover, Tool Rest, Sample Belt

Extra Accessories:

- Abrasive Belt

Specifications

| MODEL NO. | H.P. | K.W. | R.P.M | PHASE | BELT

SIZE |

RUBBER

WHEEL

|

APPROX WT. KG. |

|---|---|---|---|---|---|---|---|

| RBG-16 | 2 | 1.5 | 2800 | 3 | 50 X 2000 | 25 X 50 X250 | 95 |

| RBG-17 | 3 | 2.2 | 2800 | 3 | 50 X 2000 | 25 X 50 X250 | 97 |

| RBG-18 | 2 | 1.5 | 2800 | 1 | 50 X 2000 | 25 X 50 X250 | 95 |

| All dimensions are in mm. 3 phase model = 440 Volts 1 phase model = 230 Volts |

|||||||